When right speed for maximum perfection counts.

When right speed for maximum perfection counts.

Optical measuring systems from Qsigma.

Qsigma:

Big in small

tolerances

Quality control is a must. Should it be reliable, non-destructive, precise and fast?

Then Qsigma is your contact when it comes to inspecting form and tolerances.

Optical measuring concepts with lasers, various lighting concepts, cameras or other sensors can be realized to optimize your measuring task.

MEASURABLE COMPETENCIES.

Up to

per second.

Up to

under optimal conditions.

From prototype construction to

thanks to individual solutions.

Up to

of the workpieces.

Up to

of the workpieces.

Qsigma: precision

When right speed for maximum perfection counts.

You want to:

Improve your cycle times through faster quality controls?

Increase the measurement accuracy and optimize yield?

Easily integrate your measuring systems into the manufacturing process?

Achieve the required accuracy which you cannot achieve with current available resources?

Have a central contact person for measuring devices and evaluation software?

Map a complex measurement task internally, which was previously not possible?

Qsigma: Measure better

More quality for your individual measurement requirements.

accuracy

Cycle time

Integration capability

Integration in production systems, automatic feeding of test parts, monitoring of process compatibility, data transfer and product tracing are important for efficient production. Implementing these requirements and taking the optimization of cycle times into account is the expertise of Qsigma.

InnoMeas software

The core is our user-friendly InnoMeas software platform and it is the central communication and reporting interface between the measurement systems and the customer infrastructure and provides everything you need to record, visualize and evaluate your measurement data.

Keeping an eye on costs

Due to the modularity of the InnoMeas software platform and the scalability / expandability of the measuring systems, needs-based, cost-optimized solutions can be implemented that meet your requirement profile.

Qsigma: Measurement methods

Speed up and improve quality.

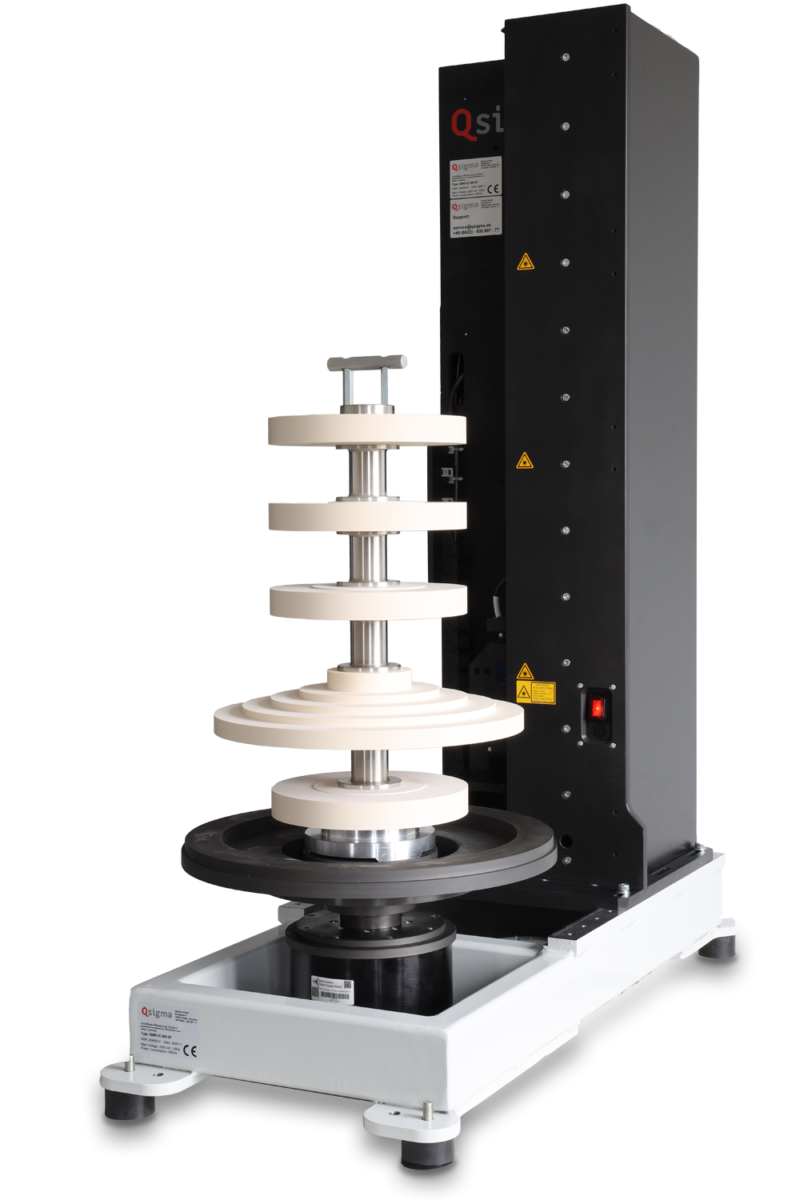

Point sensor-based

The high resolution of point sensors in combination with rotary or XYZ measurement setups is particularly useful here.

Line sensor-based

Line sensor-based systems can also be combined with the point sensor system in order to combine both advantages.

Profile projection

Both high resolution for small objects and fast data acquisition for large objects are possible.

Grid-based measurement approach

The grid-based method is suitable for area scanning or

if the test object is solely in the optimal measuring range of the sensor.

ZUR MESSMETHODE

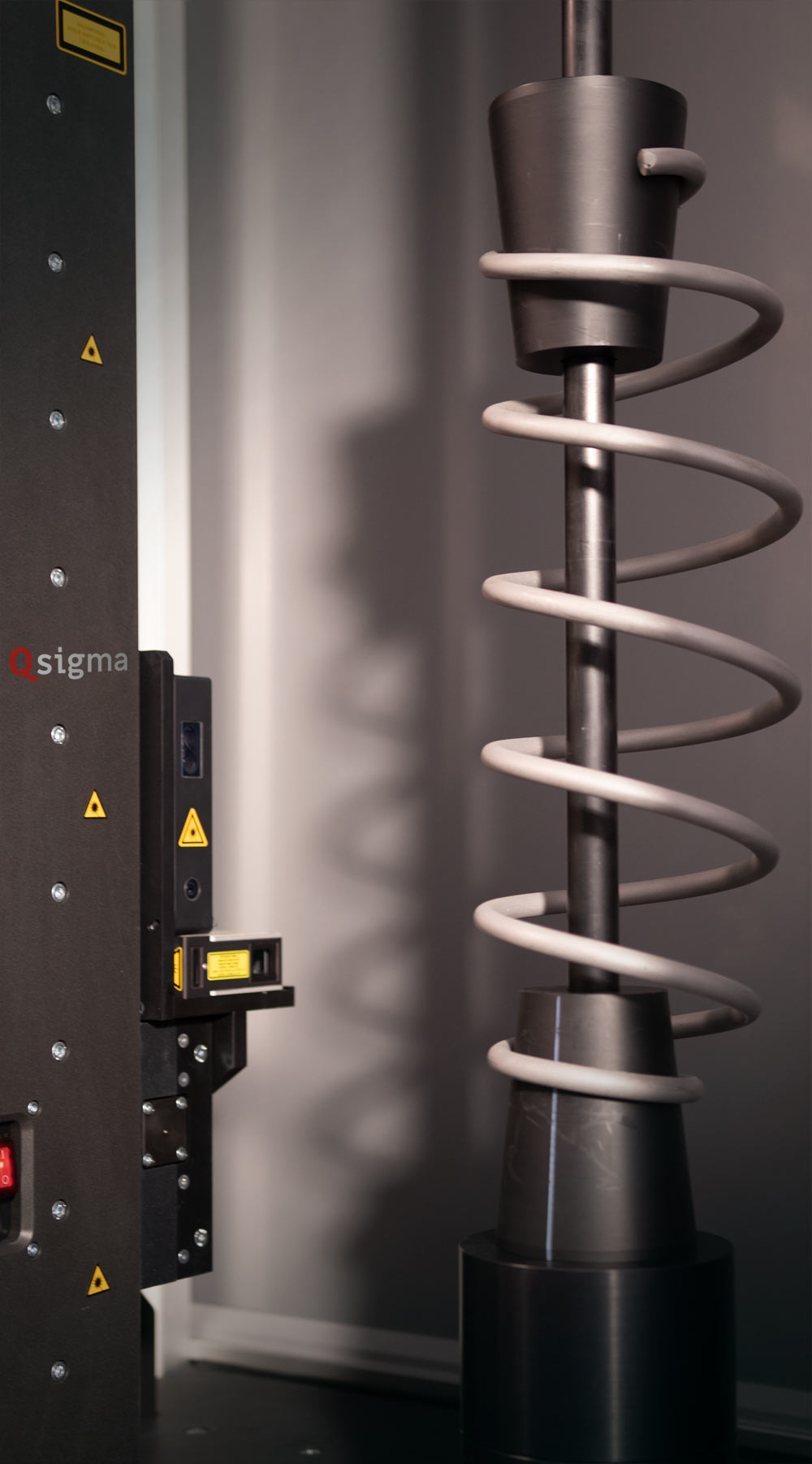

Path tracing measurement approach

Path tracing is suitable when recording complex objects such as suspension springs, as well as geometries that are difficult to access, where the grid-based method does not provide the desired accuracy.

ZUR MESSMETHODE

Qsigma: Our advantage

We solve problems due to single source hardware and software development.

Qsigma hardware

Reliable sensors with efficient software form the basis for industrial measurement systems.

Are you not satisfied with “standard”? We neither.

Our measuring systems are optimized to customer requirements and designed so that they can be easily integrated into your infrastructure.

Qsigma software

The software platform is the core of our measuring systems. The in-house development is user-friendly and offers plenty of scope for individual adjustments and evaluations.

EFFICIENCY is a top priority:

The support of various interfaces enables a smooth flow of information between the measuring and manufacturing systems.

Thanks to integrated assistance systems you can change measurement templates quickly and intuitively.

Qsigma:

Give us your measurement task!

Challenge us!

Inspire us!

Are you facing a complex measurement task? Involve Qsigma in finding the solution. Because we enjoy getting to the root of problems and developing a solution that fits your requirements.

We analyse your measurement task, carry out a feasibility study and discuss with you the integration into your special environment.

Please contact us. We take care of your individual measurement concerns and look forward to your ideas!