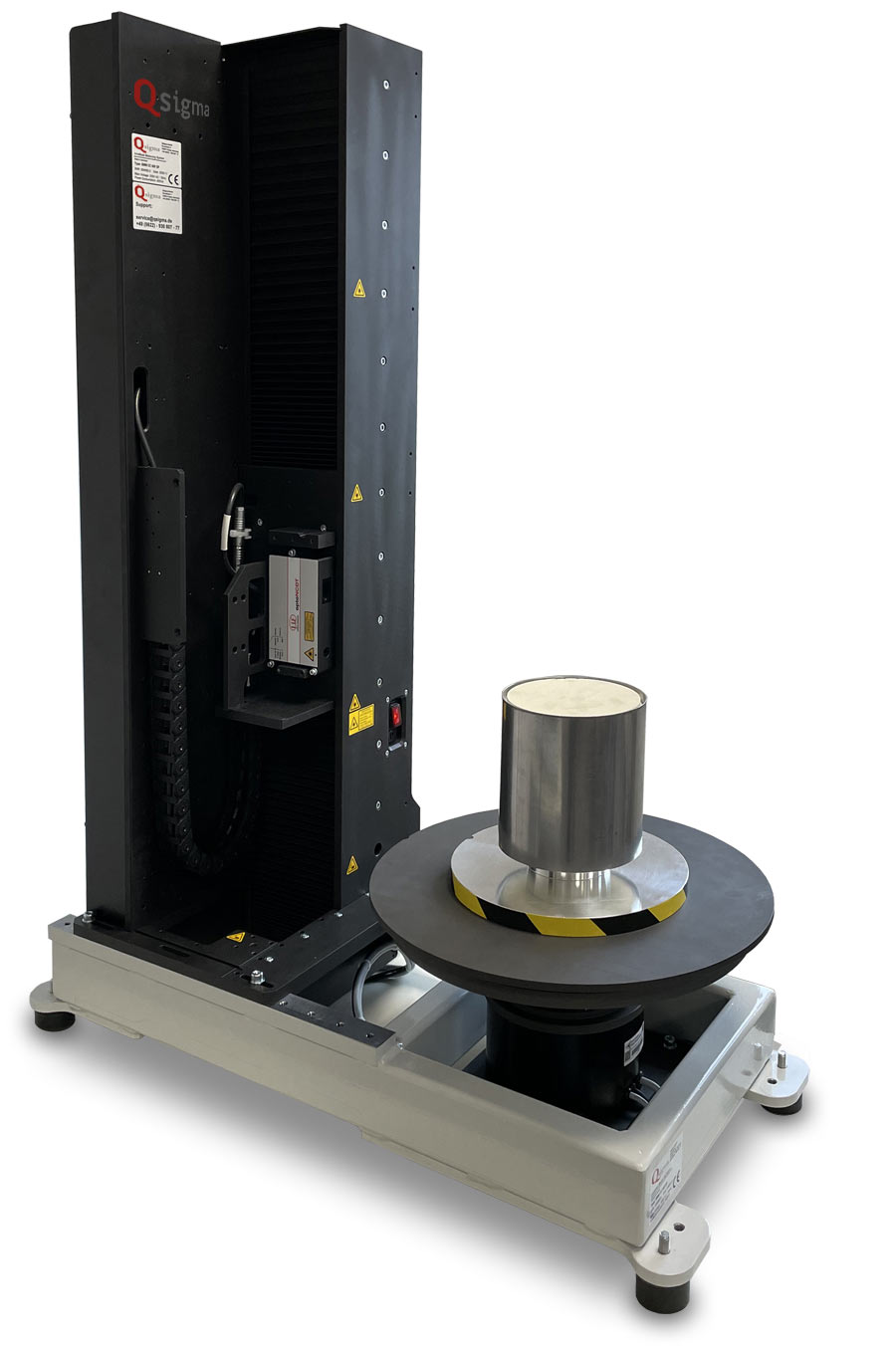

Qsigma Point-based sensors

System concept using the example of catalytic converter production.

From the point of view of production process optimization, catalytic converters and diesel particle filters are subject to high quality assurance requirements due to the increased emissions standards.

The geometry of the components to be measured is measured before and after the canning process. Important process parameters for the control of the production result from this measurement data.

The InnoMeas software suite takes over the entire evaluation according to current production specifications such as GM Appendix E1, VW PV 3225 or Mercedes Benz measuring instruction A 005 000 4099.

POINT AND LINE BASED SENSORS IN ACTION

Watch the video

Qsigma Point-based sensors

For convex shapes, modular and expandable.

From project to product

The Qsigma measuring systems are an ideal solution for use from product development through prototype construction to series production. The high resolution of the point sensors in connection with the exact angle encoder of the turntable enables the local evaluation of contours, diameters, radii as well as shape and position tolerances.

This applies to all convex shapes, be it circles, ovals or any cross-section composed of arcs and lines.

Modularity is the key

The measuring systems have a modular structure and can therefore be expanded with other sensors. For example a line sensor can be integrated to detect broken edges and determine the component height.

Qsigma:

Give us your measurement task!

Challenge us!

Inspire us!

Are you facing a complex measurement task? Involve Qsigma in finding the solution. Because we enjoy getting to the root of problems and developing a solution that fits your requirements.

We analyse your measurement task, carry out a feasibility study and discuss with you the integration into your special environment.

Please contact us. We take care of your individual measurement concerns and look forward to your ideas!